How to reduce operational costs: Proven Strategies

Discover proven tips on how to reduce operational costs effectively without sacrificing quality. Boost your bottom line today!

Mapping Your Cost Landscape: What's Really Draining Your Budget

Before making meaningful cuts to your operational costs, it's essential to understand where your money is going. This requires more than a cursory glance at your main expenses. You need to delve into the hidden cost centers that can quietly drain your budget. These can include obvious expenses like facilities and utilities, but also less obvious ones like IT infrastructure and even office supplies.

One of the first steps is a comprehensive cost analysis. This involves carefully categorizing and examining every expense to uncover both major cost drains and smaller inefficiencies. For instance, your energy usage might be higher than industry averages, or you might be paying for redundant software subscriptions. This analysis provides the basis for informed cost-cutting decisions.

It's also important to establish practical frameworks for categorizing expenses. This goes beyond standard accounting and can reveal hidden opportunities. This helps distinguish between strategic cost optimization and short-sighted budget cuts. While cutting costs might bring temporary relief, reducing crucial services or investments can hinder long-term growth. Cost optimization isn't about indiscriminate cuts; it's about strategically allocating resources for maximum efficiency and profit.

One effective way to reduce operational costs is through strategic sourcing and contract renegotiation. For example, a company paying $5,000 monthly for HVAC maintenance negotiated a 20% discount with a new vendor, reducing the cost to $4,000 per inspection. By decreasing inspections from monthly to bi-monthly, they saved an additional $24,000 annually, for a total annual savings of $36,000. This highlights the potential savings from smart procurement and service utilization. Learn more about this: Learn more about tracking cost savings and cost avoidance.

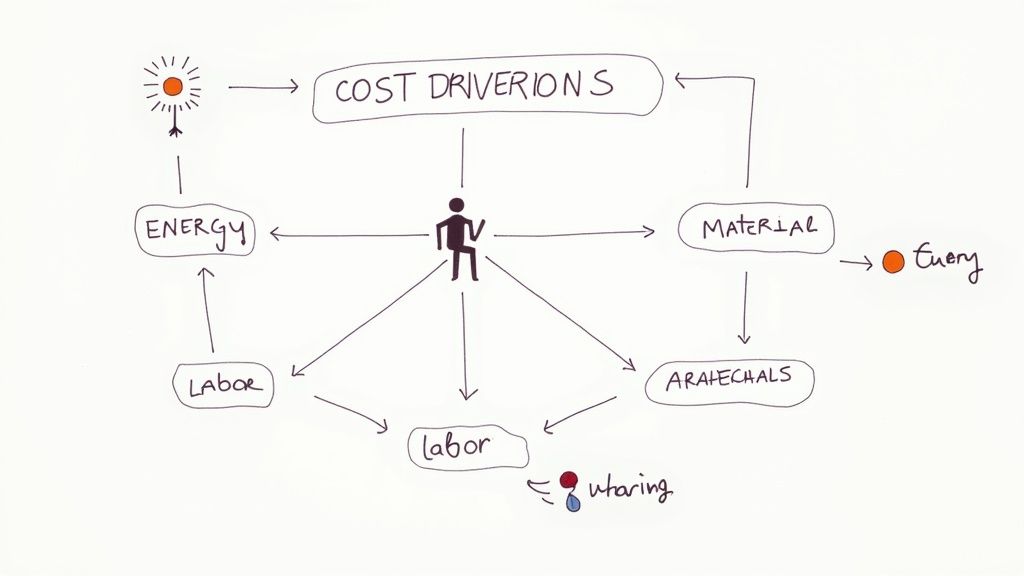

Identifying Key Cost Drivers

After gaining a comprehensive understanding of your spending, the next step is identifying key cost drivers. These are the factors with the greatest influence on your overall operational costs. This might include analyzing areas like:

- Labor Costs: Review expenses related to salaries, benefits, and overtime.

- Material Costs: Monitor costs for raw materials, components, and packaging.

- Overhead Costs: Examine expenses like rent, utilities, and administrative costs.

- Technology Costs: Assess costs for software licenses, hardware maintenance, and cloud computing.

Understanding these key drivers allows you to prioritize your cost reduction efforts and focus on areas with the greatest potential for savings. This focused approach ensures maximum impact, paving the way for more efficient operations and financial stability. This detailed analysis lays the groundwork for a more sustainable and efficient business model.

Transforming Procurement: From Cost Center to Savings Engine

Many businesses view procurement as just another cost of doing business. However, smart companies are realizing that procurement can be a powerful tool to drive significant savings. It’s about shifting from simply buying goods and services to strategically finding the best possible value.

Strategies For Procurement Optimization

Several key strategies can dramatically improve your bottom line. For example, supplier consolidation allows you to negotiate from a position of strength. Fewer vendors mean better leverage for lower prices and more favorable terms.

Volume leverage is another important factor. Buying in bulk often unlocks significant discounts, reducing your per-unit costs. Combining fewer suppliers with larger orders can lead to substantial savings.

Competitive bidding is also essential. Getting bids from multiple suppliers ensures you're always paying the most competitive price in the market.

Beyond these core strategies, renegotiating current contracts offers further opportunities for savings. This doesn't have to be a combative process. A collaborative approach, focused on mutual gain, can often lead to better terms for everyone. For instance, offering a longer contract in exchange for a reduced price can benefit both you and your supplier.

Optimizing Service Contracts For Savings

Another often-overlooked area for savings is service frequency optimization. Do you really need daily deliveries, or would twice a week suffice? Carefully evaluating service contracts and adjusting frequencies based on real needs can significantly cut recurring expenses.

The following table summarizes several procurement cost reduction strategies, their implementation difficulty, the expected time to see results, and potential savings.

Procurement Cost Reduction Strategies

| Strategy | Implementation Difficulty | Time to Results | Potential Savings |

|---|---|---|---|

| Supplier Consolidation | Low | Short-term | Medium |

| Volume Leverage | Medium | Short-term | High |

| Competitive Bidding | Medium | Short-term | Medium |

| Contract Renegotiation | High | Medium-term | Medium |

| Service Frequency Optimization | Low | Short-term | Low to Medium |

This table highlights the potential impact of different procurement approaches. While some strategies, like volume leverage, offer high potential savings, others like service frequency optimization might yield smaller but still valuable gains. It's crucial to consider both the potential savings and the implementation difficulty when choosing the right strategy.

The Power of Digital Procurement Platforms

Digital procurement platforms like SAP Ariba are revolutionizing how businesses manage their spending. These platforms provide detailed insights into spending patterns, highlighting areas for improvement. They also automate administrative tasks, allowing your team to focus on strategic activities. This increased efficiency directly translates into cost savings and improved accuracy and compliance. You might be interested in: How to master business process optimization.

Vendor Management Frameworks

Effective vendor management is critical for maximizing cost savings. Clear frameworks for vendor selection, performance evaluation, and contract negotiation ensure consistency across your organization. This structured approach helps you consistently get the best value. These frameworks should be flexible enough for different departments while aligning with overall business goals. For example, a vendor scoring system allows for objective evaluations based on price, quality, and reliability.

By actively implementing these procurement strategies, you can transform your procurement process from a cost center into a powerful engine for savings. This proactive approach not only reduces costs but also strengthens your financial position and contributes to overall business success.

Get started with your lifetime license

Enjoy unlimited conversations with MultitaskAI and unlock the full potential of cutting-edge language models—all with a one-time lifetime license.

Demo

Free

Try the full MultitaskAI experience with all features unlocked. Perfect for testing before you buy.

- Full feature access

- All AI model integrations

- Split-screen multitasking

- File uploads and parsing

- Custom agents and prompts

- Data is not saved between sessions

Lifetime License

Most Popular€99€149

One-time purchase for unlimited access, lifetime updates, and complete data control.

- Everything in Free

- Data persistence across sessions

- MultitaskAI Cloud sync

- Cross-device synchronization

- 5 device activations

- Lifetime updates

- Self-hosting option

- Priority support

Loved by users worldwide

See what our community says about their MultitaskAI experience.

Finally found a ChatGPT alternative that actually respects my privacy. The split-screen feature is a game changer for comparing models.

Sarah

Been using this for months now. The fact that I only pay for what I use through my own API keys saves me so much money compared to subscriptions.

Marcus

The offline support is incredible. I can work on my AI projects even when my internet is spotty. Pure genius.

Elena

Love how I can upload files and create custom agents. Makes my workflow so much more efficient than basic chat interfaces.

David

Self-hosting this was easier than I expected. Now I have complete control over my data and conversations.

Rachel

The background processing feature lets me work on multiple conversations at once. No more waiting around for responses.

Alex

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

Finally found a ChatGPT alternative that actually respects my privacy. The split-screen feature is a game changer for comparing models.

Sarah

Been using this for months now. The fact that I only pay for what I use through my own API keys saves me so much money compared to subscriptions.

Marcus

The offline support is incredible. I can work on my AI projects even when my internet is spotty. Pure genius.

Elena

Love how I can upload files and create custom agents. Makes my workflow so much more efficient than basic chat interfaces.

David

Self-hosting this was easier than I expected. Now I have complete control over my data and conversations.

Rachel

The background processing feature lets me work on multiple conversations at once. No more waiting around for responses.

Alex

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

Finally found a ChatGPT alternative that actually respects my privacy. The split-screen feature is a game changer for comparing models.

Sarah

Been using this for months now. The fact that I only pay for what I use through my own API keys saves me so much money compared to subscriptions.

Marcus

The offline support is incredible. I can work on my AI projects even when my internet is spotty. Pure genius.

Elena

Love how I can upload files and create custom agents. Makes my workflow so much more efficient than basic chat interfaces.

David

Self-hosting this was easier than I expected. Now I have complete control over my data and conversations.

Rachel

The background processing feature lets me work on multiple conversations at once. No more waiting around for responses.

Alex

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

Finally found a ChatGPT alternative that actually respects my privacy. The split-screen feature is a game changer for comparing models.

Sarah

Been using this for months now. The fact that I only pay for what I use through my own API keys saves me so much money compared to subscriptions.

Marcus

The offline support is incredible. I can work on my AI projects even when my internet is spotty. Pure genius.

Elena

Love how I can upload files and create custom agents. Makes my workflow so much more efficient than basic chat interfaces.

David

Self-hosting this was easier than I expected. Now I have complete control over my data and conversations.

Rachel

The background processing feature lets me work on multiple conversations at once. No more waiting around for responses.

Alex

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

The sync across devices works flawlessly. I can start a conversation on my laptop and continue on my phone seamlessly.

James

As a developer, having all my chats, files, and agents organized in one place has transformed how I work with AI.

Sofia

The lifetime license was such a smart purchase. No more monthly fees, just pure productivity.

Ryan

Queue requests feature is brilliant. I can line up my questions and let the AI work through them while I focus on other tasks.

Lisa

Having access to Claude, GPT-4, and Gemini all in one interface is exactly what I needed for my research.

Mohamed

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

The sync across devices works flawlessly. I can start a conversation on my laptop and continue on my phone seamlessly.

James

As a developer, having all my chats, files, and agents organized in one place has transformed how I work with AI.

Sofia

The lifetime license was such a smart purchase. No more monthly fees, just pure productivity.

Ryan

Queue requests feature is brilliant. I can line up my questions and let the AI work through them while I focus on other tasks.

Lisa

Having access to Claude, GPT-4, and Gemini all in one interface is exactly what I needed for my research.

Mohamed

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

The sync across devices works flawlessly. I can start a conversation on my laptop and continue on my phone seamlessly.

James

As a developer, having all my chats, files, and agents organized in one place has transformed how I work with AI.

Sofia

The lifetime license was such a smart purchase. No more monthly fees, just pure productivity.

Ryan

Queue requests feature is brilliant. I can line up my questions and let the AI work through them while I focus on other tasks.

Lisa

Having access to Claude, GPT-4, and Gemini all in one interface is exactly what I needed for my research.

Mohamed

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Switched from ChatGPT Plus and haven't looked back. This gives me access to all the same models with way more features.

Maya

The sync across devices works flawlessly. I can start a conversation on my laptop and continue on my phone seamlessly.

James

As a developer, having all my chats, files, and agents organized in one place has transformed how I work with AI.

Sofia

The lifetime license was such a smart purchase. No more monthly fees, just pure productivity.

Ryan

Queue requests feature is brilliant. I can line up my questions and let the AI work through them while I focus on other tasks.

Lisa

Having access to Claude, GPT-4, and Gemini all in one interface is exactly what I needed for my research.

Mohamed

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Dark mode, keyboard shortcuts, and the clean interface make this a joy to use daily.

Carlos

Fork conversations feature is perfect for exploring different ideas without losing my original train of thought.

Aisha

The custom agents with specific instructions have made my content creation process so much more streamlined.

Thomas

Best investment I've made for my AI workflow. The features here put other chat interfaces to shame.

Zoe

Privacy-first approach was exactly what I was looking for. My data stays mine.

Igor

The PWA works perfectly on mobile. I can access all my conversations even when I'm offline.

Priya

Support team is amazing. Quick responses and they actually listen to user feedback for improvements.

Nathan

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Dark mode, keyboard shortcuts, and the clean interface make this a joy to use daily.

Carlos

Fork conversations feature is perfect for exploring different ideas without losing my original train of thought.

Aisha

The custom agents with specific instructions have made my content creation process so much more streamlined.

Thomas

Best investment I've made for my AI workflow. The features here put other chat interfaces to shame.

Zoe

Privacy-first approach was exactly what I was looking for. My data stays mine.

Igor

The PWA works perfectly on mobile. I can access all my conversations even when I'm offline.

Priya

Support team is amazing. Quick responses and they actually listen to user feedback for improvements.

Nathan

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Dark mode, keyboard shortcuts, and the clean interface make this a joy to use daily.

Carlos

Fork conversations feature is perfect for exploring different ideas without losing my original train of thought.

Aisha

The custom agents with specific instructions have made my content creation process so much more streamlined.

Thomas

Best investment I've made for my AI workflow. The features here put other chat interfaces to shame.

Zoe

Privacy-first approach was exactly what I was looking for. My data stays mine.

Igor

The PWA works perfectly on mobile. I can access all my conversations even when I'm offline.

Priya

Support team is amazing. Quick responses and they actually listen to user feedback for improvements.

Nathan

The file parsing capabilities saved me hours of work. Just drag and drop documents and the AI understands everything.

Emma

Dark mode, keyboard shortcuts, and the clean interface make this a joy to use daily.

Carlos

Fork conversations feature is perfect for exploring different ideas without losing my original train of thought.

Aisha

The custom agents with specific instructions have made my content creation process so much more streamlined.

Thomas

Best investment I've made for my AI workflow. The features here put other chat interfaces to shame.

Zoe

Privacy-first approach was exactly what I was looking for. My data stays mine.

Igor

The PWA works perfectly on mobile. I can access all my conversations even when I'm offline.

Priya

Support team is amazing. Quick responses and they actually listen to user feedback for improvements.

Nathan

Tech-Driven Efficiency: Tools That Actually Pay For Themselves

Having explored procurement optimization and cost mapping, let's shift our focus to strategically deploying technology to reduce operational costs. This means finding and implementing tools that offer a substantial return on investment (ROI), transforming expenses instead of just adding new ones.

Evaluating Tech Investments for Long-Term Savings

Many businesses make the mistake of focusing only on upfront costs when evaluating new technologies. A smarter approach is to consider the Total Cost of Ownership (TCO). This includes not only the initial price but also ongoing maintenance, training, and integration expenses. For instance, a seemingly inexpensive software might require extensive customization and training, ultimately becoming more expensive than a slightly pricier, user-friendly option.

Another crucial factor is automation. Automating repetitive tasks frees up employee time, allowing them to focus on more valuable work. This boosts productivity and reduces labor costs, significantly impacting operational expenses. Want to dive deeper into process optimization? Check out this helpful resource: How to master process optimization techniques.

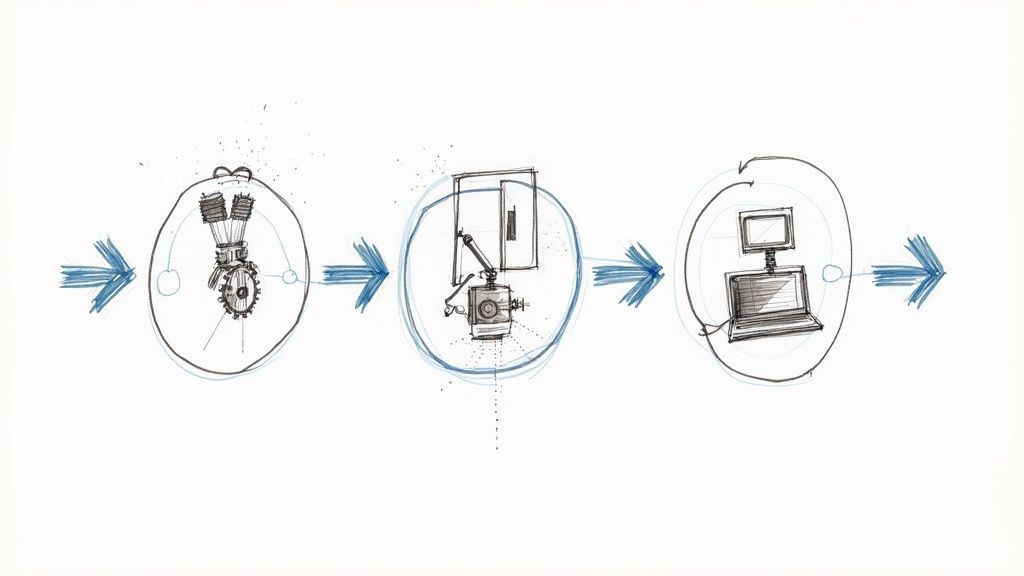

The Power of Cloud Migration and AI Applications

Migrating to the cloud can lead to significant cost savings by reducing the need for on-premises hardware and IT personnel. Cloud solutions also offer greater scalability and flexibility, adapting to changing business needs. Similarly, AI applications can optimize various processes, from customer service to predictive maintenance. Careful evaluation is key to ensuring these technologies align with your specific business needs and contribute to a lower TCO.

The learning curve effect is another powerful cost-reduction tool. As organizations gain experience with producing or implementing technologies, their efficiency improves, leading to lower costs. The Environmental Protection Agency (EPA) found that costs decrease by roughly 20% with each doubling of cumulative production volume. This principle highlights how experience and scale can drive down expenses. Find more detailed statistics here.

Practical Implementation for Maximum Impact

Successful tech implementation requires a strategic, disruption-minimizing approach that maximizes adoption rates. This involves thorough training programs so employees can effectively use the new tools. Clearly communicating the benefits of these technologies is crucial for team-wide buy-in. This collaborative approach ensures that tech investments translate into real cost savings and improved operational efficiency.

Examples of Tech-Driven Cost Reduction

Predictive Maintenance: Data analysis anticipates equipment failures, enabling proactive maintenance and preventing costly downtime. This proactive approach minimizes disruption and extends equipment lifespan.

Workflow Automation: Automating repetitive tasks, such as data entry or report generation, saves employee time and reduces human error. This streamlines operations and empowers staff to focus on strategic initiatives.

By embracing these tech-driven strategies, businesses can achieve substantial and sustainable operational cost reductions. These tools not only cut expenses but also pave the way for improved efficiency, productivity, and long-term growth.

Energy Revolution: Turning Resource Drains Into Savings

For many businesses, a large chunk of operating costs goes towards paying utility bills. However, this is often an area ripe with untapped potential for significant savings. This section explores practical ways to optimize energy use and enjoy immediate financial benefits without needing major capital investments.

Conducting a DIY Energy Audit

One of the first steps towards reducing energy consumption is understanding where your energy is actually going. A DIY energy audit can pinpoint areas of waste and highlight high-impact changes you can make. This involves a systematic review of your facility's energy usage, covering everything from lighting and HVAC systems to office equipment and appliances.

You might find, for instance, that old lighting fixtures are using excessive electricity. Or perhaps drafty windows and doors are contributing to significant heat loss. Identifying these issues is the first step to fixing them.

Tactical Strategies For Energy Reduction

Once you've identified areas for improvement, you can implement a range of tactical strategies to cut energy costs. These include behavioral changes and targeted infrastructure upgrades. For example, a company-wide policy to switch off lights and computers when not in use can make a real difference in electricity consumption.

Installing smart thermostats can optimize heating and cooling schedules, resulting in further savings. Upgrading to energy-efficient appliances and equipment can also lead to substantial long-term cost reductions.

Exploring Renewable Energy Options

Renewable energy sources like solar and wind power are becoming increasingly affordable. They offer a great way to reduce your reliance on traditional energy sources and lower operating costs. In the renewable energy sector, especially with solar photovoltaic (PV) systems, significant cost reductions have been seen.

Between 2010 and 2020, the cost of residential, commercial-rooftop, and utility-scale PV systems decreased by 64%, 69%, and 82%, respectively. The cost of a utility-scale PV system is now around $1 per watt, down from $2.50 a decade ago. Learn more about these declining solar costs. By using renewable energy, businesses can achieve substantial long-term savings and reduce their environmental impact.

Policy Adjustments and Employee Engagement

While technology and infrastructure are important, policy adjustments and employee engagement programs can also significantly affect energy use. Implementing clear guidelines for energy use, incentivizing energy-saving behaviors, and educating employees about energy conservation can create a culture of sustainability.

This approach not only reduces operating costs but also builds a more environmentally responsible organization. See how efficient workflows contribute to energy savings in our guide on workflow automation benefits.

The following table, "Energy Cost Reduction Measures", presents several energy-saving initiatives, their typical implementation costs, potential annual savings, and estimated payback periods. This information provides a clear overview of the financial benefits associated with each initiative.

| Initiative | Implementation Cost | Annual Savings | Payback Period |

|---|---|---|---|

| LED Lighting Retrofit | $5,000 | $1,500 | 3.3 years |

| Smart Thermostat Installation | $500 | $200 | 2.5 years |

| Building Insulation Upgrade | $10,000 | $2,500 | 4 years |

As you can see, the initial investment can be recouped relatively quickly through reduced energy expenses. By actively managing energy consumption, businesses can achieve substantial and lasting cost reductions. This is good for their bottom line and good for the environment. These strategies empower organizations to be more efficient and sustainable.

Workforce Optimization: Beyond the Obvious Labor Savings

Labor costs often represent the largest operational expense for any business. However, reducing these costs isn't about indiscriminate cuts. It requires a strategic approach focused on workforce optimization to improve efficiency and productivity while maintaining quality and employee morale.

Identifying Bottlenecks and Redundancies

One of the first steps in workforce optimization is identifying bottlenecks and redundancies. These inefficiencies waste valuable staff time and can lead to unnecessary overtime expenses. A detailed analysis of your processes, often through process mapping and workflow analysis, can reveal these hidden costs. For example, a company might discover that a lengthy approval process is causing significant delays, or that several employees are performing the same data entry tasks.

Implementing Flexible Staffing Models

Traditional staffing models, with their fixed schedules, don't always align with actual demand. Flexible staffing models, however, adapt to fluctuating workloads. This could involve using part-time employees, on-call staff, or adjusting shift patterns based on real-time needs. This approach ensures you have the right number of people working at the right times, minimizing both understaffing and overstaffing.

Cross-Training and Strategic Outsourcing

Cross-training employees to perform multiple roles creates a more versatile and resilient workforce. It reduces the need for specialized hires and allows employees to cover for each other during absences or peak periods. Additionally, strategic outsourcing can be a cost-effective solution for non-core functions. By outsourcing tasks like IT support or payroll services, companies free up internal resources to focus on core business activities.

Performance-Based Incentives

While reducing labor costs is important, maintaining employee motivation and productivity is crucial. Performance-based incentives can achieve both. Rewarding employees for meeting specific goals or exceeding expectations drives productivity improvements while potentially reducing overall labor expenses. This creates a win-win for both the company and its employees. Examples include bonuses for sales teams exceeding targets, or rewards for customer service teams achieving high satisfaction scores.

Practical Implementation

Workforce optimization requires careful planning and execution. Start by analyzing current staffing levels and identifying areas for improvement. Implement changes gradually, maintaining clear communication with employees throughout the process. Regularly monitor results and adjust your strategy as needed. This measured approach ensures a smooth transition and maximizes the positive impact on your bottom line, allowing you to reduce operational costs without sacrificing employee morale or product quality.

No spam, no nonsense. Pinky promise.

Lean Transformation: Eliminating the 8 Hidden Wastes

Lean methodology offers a powerful framework for finding and eliminating waste, leading to significant cuts in operational costs. Many organizations, however, struggle to implement it effectively outside of manufacturing. This section explains key lean principles and shows how they can be applied across different business functions.

Understanding the 8 Wastes

Lean methodology centers around eliminating eight types of waste, known as "muda" in Japanese. These wastes represent anything that doesn’t add value to the final product or service. They are:

- Defects: Errors, rework, and scrap materials drive up costs and waste time.

- Overproduction: Making more than needed creates excess inventory and storage costs.

- Waiting: Idle time from bottlenecks or delays wastes resources and lowers efficiency.

- Non-Utilized Talent: Not using employee skills and knowledge fully leads to lost potential and lower productivity. This ties into workforce optimization, where maximizing employee contribution is crucial.

- Transportation: Unnecessary movement of materials or information increases cost and complexity.

- Inventory: Holding too much inventory ties up capital and raises storage and obsolescence risks. This highlights the importance of strong procurement practices.

- Motion: Unnecessary movement of people or equipment wastes time and energy.

- Excess Processing: Doing more steps than needed adds complexity and cost without adding value. This relates to automating tasks with technology to streamline workflows and improve overall efficiency.

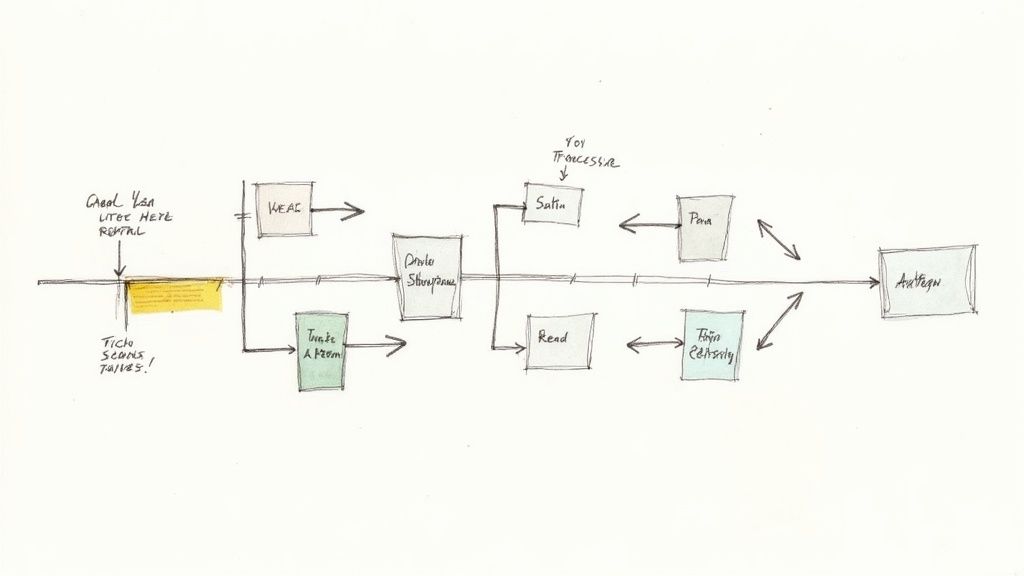

Value Stream Mapping: Visualizing Waste

Value stream mapping is a lean tool that visually shows all the steps involved in delivering a product or service. This lets businesses pinpoint areas of waste and inefficiency in their processes. For example, a hospital could map the patient journey from admission to discharge, revealing bottlenecks in patient flow or excessive paperwork. This visualization helps target interventions to eliminate those wastes.

Actionable Techniques for Waste Reduction

Dealing with these eight wastes requires a varied approach. For defects, implementing quality control measures and root cause analysis helps minimize errors. For overproduction, techniques like Just-in-Time (JIT) manufacturing can match production to actual demand. Minimizing waiting time often means optimizing workflows and improving communication between teams. These practical steps turn lean principles into real cost savings.

Building a Continuous Improvement Culture

Lean transformation isn’t a one-time project, but an ongoing journey. Building a continuous improvement culture is vital for lasting success. This means empowering employees at every level to identify and eliminate waste. Regularly reviewing processes, getting feedback, and making small, incremental changes create a cycle of continuous improvement. This long-term approach aligns with the strategic goal of cost reduction as a driver of growth and efficiency.

Lean in Action: Real-World Examples

From healthcare to professional services, lean principles have proven their cost-saving power across many industries. A law firm, for instance, could use lean principles to streamline document management, reducing paper waste and boosting efficiency. This cross-industry applicability reinforces the broad relevance of lean methodology for cutting operational costs. These examples show that lean transformation isn't just theory, but a practical approach with measurable results. By adopting these principles, organizations can achieve significant cost savings without sacrificing quality or needing major capital investment.